Fire pumps

Supplying fire pumps of all kinds and sizes (individual – electricity – or dual – electricity and a jockey – or triple – auxiliary pump and a jockey auxiliary pump and diesel engine) with all its accessories (national assembly – Chinese – German – American)

• Non UL

• UL Listed

• FM Approved

The fire pump is part of the water supply for the fire sprinkler system and is powered by electricity, diesel or steam. The pump connection is either connected to the general groundwater supply network, or to a fixed water source (for example, reservoir, lake, etc.).

The pump provides water flow at a higher pressure for the spray system jacks and hoses. The fire pump is tested and listed for use specifically for fire service by an external test agency and list, such as UL or FM Global. The main code governing fire pump installations in North America is the NFPA 20 standard issued by the National Fire Protection Association to install stationary fire protection fire pumps.

Fire pumps work either with an electric motor or a diesel engine, or sometimes a steam turbine. If the local construction symbol requires power independent of the local electric power grid, the pump that uses an electric motor, when connected via a included switch, may use the installation of the emergency generator.

The fire pump starts when the pressure in the fire sprinkler system drops below the threshold. The pressure of the spray system decreases significantly when one or more fire sprinklers are exposed to heat over their design temperature, opens, and releases water. Alternately, other fire hose reels or other fire-fighting joints are opened, resulting in a pressure drop in the main fire-fighting switch.

Fire pumps are needed when the local municipal water system cannot provide enough pressure to meet the hydraulic design requirements of the fire sprinkler system. This usually occurs if the building is very tall, as in high-rise buildings, or in systems that require relatively high longitudinal pressure at a fire sprinkler in order to save a large amount of water, such as in a warehouse. Fire pumps are also needed if a water supply is provided to protect from fire from a ground-level water storage tank.

Types of pumps used for extinguishing service include: horizontal split box, vertical split box, vertical line, vertical turbine, and end suction.

Jockey Auxiliary Pump

Auxiliary pump is a small pump connected to the fire sprinkler system and aims to keep the pressure in the fire protection piping system to an artificially high level so that the operation of one fire sprinkler will lower the pressure that an automatic control of the fire pump will feel, which will trigger the fire pump. Auxiliary pump is an essential part of the fire pump control system. The auxiliary pump is of lower flow volume than flow to one sprinkler to ensure low system pressure. Jockey pumps are usually small multi-stage centrifugal pumps, and they do not have to be inserted or approved for fire system use. However, control equipment for auxiliary pumps may carry approvals. Jockey pumps should be 3% of the main fire pump flow and provide 10psi more pressure than the main fire pump

Diesel pump

It is used as an auxiliary pump in the event of a power outage at the site

مخارج طوارئ مضيئه

Flashing emergency exits are signs and signals that help individuals identify the escape route and emergency exits inside the building in the event

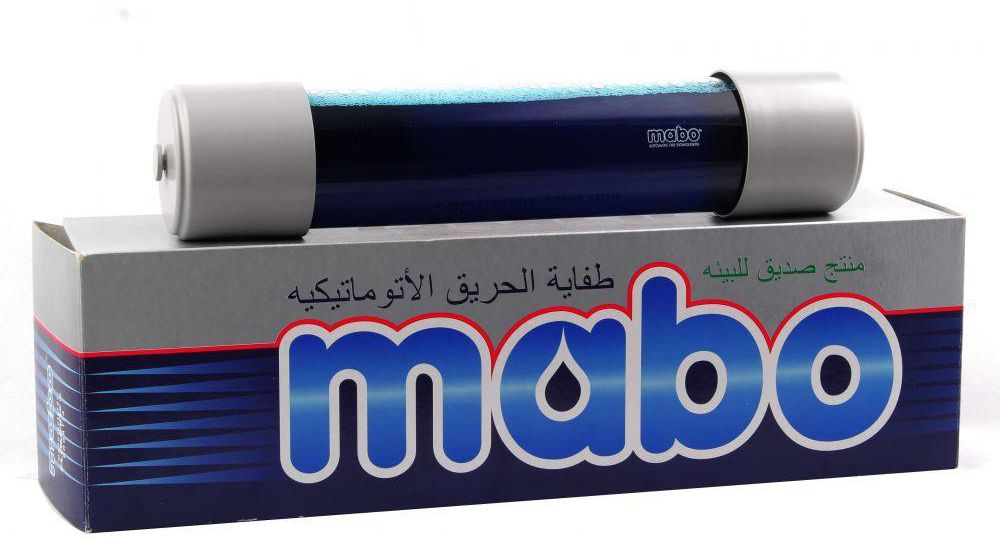

Jun 14, 2021طفايات الحريق المطورة مابو

طفايات الحريق المبتكرة: مابو طفاية حريق اوتوماتيكية ، تقوم بإطفاء الحريق تلقائيا

Jul 28, 2020